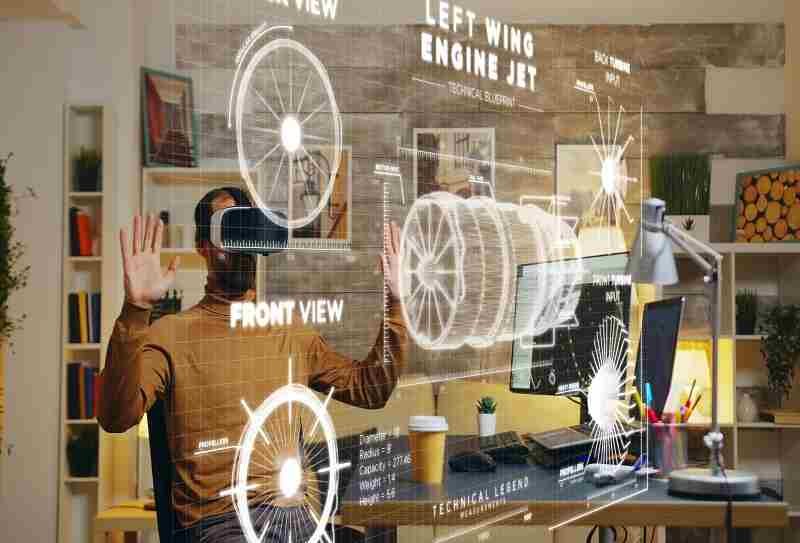

Picture this: A high-tech manufacturing plant buzzing with activity, where every second counts. Robotic systems operate seamlessly, components are assembled with near-perfect precision, and every element must perform flawlessly to keep the production line moving. In this critical environment, the VH54S.5PH6 emerges not just as a part but as the unsung hero — engineered to endure, designed to excel, and trusted to deliver when it matters most.

More than a mere code on a label, VH54S.5PH6 stands as a symbol of robust engineering and cutting-edge innovation. It’s the linchpin of reliability and precision, built for environments where failure can cost millions, delay entire projects, or even risk safety. This is a component crafted with the vision of industrial perfection in mind, balancing durability, performance, and ease of use.

At the core, the VH54S.5PH6 champions three non-negotiable pillars that make it a standout in the industrial landscape:

1. Extreme Durability Meets Unyielding Reliability

This component is forged to operate in the harshest conditions imaginable. Think intense thermal cycling from -40°C freezing to +150°C scorching heat, relentless vibrations that would disable ordinary devices, exposure to corrosive chemicals, and mechanical shocks far beyond industry norms. Thanks to advanced composite materials and state-of-the-art sealing technologies, the VH54S.5PH6 continues to perform without degradation, dramatically lowering the risk of costly failures and downtime. Its rugged construction ensures that it thrives where lesser components fail — making it ideal for remote, demanding, or mission-critical applications.

2. Pinpoint Precision and Unwavering Stability

Whether it’s controlling micron-level pressures in semiconductor fabrication or delivering exact hydraulic flows in aerospace actuators, the VH54S.5PH6 boasts accuracy that remains rock-solid over time. Drift rates are minimized to less than ±0.1% per year, ensuring consistent performance that directly translates to improved product yields, less rework, and higher overall quality. This precision stability is achieved through proprietary calibration methods, advanced sensor technologies, and high-grade materials that resist wear and environmental influence.

3. Energy-Efficient, User-Friendly Design

High performance rarely pairs with simplicity — but here it does. The VH54S.5PH6 consumes up to 30% less power than standard components, reducing operational costs and heat generation. Its modular architecture and standardized interfaces simplify installation and maintenance, saving valuable time and cutting down on the need for specialized technicians. The design prioritizes minimal footprint and compatibility with modern industrial control systems, enabling faster integration and greater scalability.

| Feature | VH54S.5PH6 Specification | Industry Average | Benefit |

|---|---|---|---|

| Operating Temperature | -40°C to +150°C | -10°C to +85°C | Operates in extreme climates |

| Vibration Resistance | Sustained 15g, Shock 50g | Sustained 5g, Shock 10g | Maintains performance in harsh vibration zones |

| Calibration Stability | Drift < ±0.1% per year | ±1-2% per year | Long-lasting accuracy |

| Power Consumption | Optimized low-power design | Standard | Reduced energy bills |

| MTBF (Mean Time Between Failures) | 100,000+ hours | 20,000-50,000 hours | Lower downtime and maintenance costs |

| Integration Time | Modular, standardized interfaces | Often custom & complex | Faster deployment and easier maintenance |

These technical specs highlight how the VH54S.5PH6 outperforms typical industrial parts in reliability, durability, and efficiency — critical factors when uptime and precision matter most.

Industrial Automation & Robotics

In robotic assembly lines, this component ensures every robotic arm operates with flawless precision. Its rugged design absorbs constant motion and mechanical shocks, guaranteeing continuous, high-quality output. When production downtime costs thousands per minute, VH54S.5PH6 reliability is mission-critical. This ensures seamless repetitive motion with zero tolerance for error, enhancing productivity and reducing costly stoppages.

Advanced Manufacturing (Semiconductors, Pharmaceuticals)

Cleanroom environments demand ultra-stable performance and contamination resistance. The VH54S.5PH6’s sealed, low-outgassing construction meets these needs, precisely controlling ultra-pure gas flows and vacuum pressures essential for microchip fabrication and sterile pharmaceutical filling. Its design adheres to stringent ISO standards for contamination control, contributing to breakthrough yields and product safety.

Aerospace & Defense

Facing brutal environmental extremes — wide temperature swings, vibration, and electromagnetic interference — this component safeguards critical flight systems from engine controls to environmental regulation, ensuring safety and compliance at 30,000 feet and beyond. Its EMI shielding and aerospace-grade certifications guarantee flawless operation in the most challenging air and space environments.

Medical Devices & Life Sciences

Surgical robots and life-support systems depend on absolute accuracy and sterility. VH54S.5PH6 excels here, regulating infusion pump flows and surgical actuators, directly contributing to patient safety and successful outcomes. Biocompatible materials and IP67+ sealing provide the required sterility and reliability for critical healthcare applications.

Energy Sector & Heavy Machinery

Operating in corrosive, high-pressure, and remote locations such as offshore oil rigs or desert mines, VH54S.5PH6’s corrosion-resistant materials and high MTBF make it indispensable for monitoring turbine pressures, hydraulic systems, and wellhead controls. It ensures reliable operation even under harsh environmental and mechanical stresses, reducing costly maintenance and downtime in the field.

| Industry | Challenge | VH54S.5PH6 Solution | Result |

|---|---|---|---|

| Aerospace | Extreme conditions & vibration | Rugged materials & advanced vibration tolerance | Safer flights, fewer maintenance issues |

| Medical Devices | Sterility & precision | IP67+ sealing, biocompatible materials | Reliable treatments, safer surgeries |

| Semiconductors | Nanometer accuracy & contamination | Ultra-stable, contamination-resistant design | Higher yields, fewer defects |

| Robotics | 24/7 operation & collision risk | High durability & shock resistance | Max uptime & quality |

| Oil & Gas | Corrosion & remote harsh environments | Corrosion-resistant alloys, wide pressure ranges | Safer, longer-lasting equipment |

This table summarizes how VH54S.5PH6 addresses core challenges industry-wide, delivering specialized benefits that outperform generic parts.

Drastically Reduced Downtime:

Unplanned failures disrupt production and inflate costs. VH54S.5PH6’s long MTBF ensures smoother operations and fewer emergency repairs. This reliability translates directly into increased profit margins and operational predictability.

Lower Energy Consumption:

Optimized design cuts electricity use, lowering utility bills and reducing environmental footprint — critical for green manufacturing initiatives. Energy efficiency also lowers heat output, extending the lifespan of surrounding equipment.

Simplified Installation & Maintenance:

Modular design, clear documentation, and standardized protocols mean faster setup and less reliance on specialized labor. This reduces training costs and accelerates deployment timelines.

Enhanced Quality, Reduced Waste:

Consistent precision means fewer rejects, improving profitability and sustainability. Lower scrap rates and rework save raw materials and boost production efficiency.

Longer Lifecycle:

Robust materials and build quality mean fewer replacements and lower total cost of ownership (TCO). Investments in VH54S.5PH6 pay off by minimizing capital expenses over the equipment lifecycle.

Engineers value VH54S.5PH6 for its compatibility and ease of use:

- Supports Standard Industrial Communication Protocols: Includes 4-20mA analog, IO-Link, Modbus, and Profinet, ensuring smooth integration with existing control systems.

- Comprehensive Documentation: Datasheets, wiring guides, and calibration instructions minimize setup errors and expedite commissioning.

- Built-in Diagnostics: Enables predictive maintenance through real-time health monitoring, helping avoid surprises and unscheduled downtime.

- Modular Parts: Allows replacement of subcomponents without full device swap, reducing maintenance costs and downtime.

- Responsive Manufacturer Support: Offers technical assistance and troubleshooting to solve integration challenges swiftly and efficiently.

This combination of features helps manufacturers stay agile, minimize risks, and maximize productivity in fast-changing environments.

Consider your application carefully:

- Do you require extreme precision and stability? If tolerances are loose, a simpler component may suffice. VH54S.5PH6 is best suited where exact performance is mandatory.

- Will it operate in harsh or demanding environments? If yes, ruggedness is essential, making this model a top choice.

- Is this a safety-critical or costly downtime scenario? The investment pays off here with superior reliability.

- Have you accounted for total cost of ownership? VH54S.5PH6 often wins over cheaper parts once all factors (maintenance, energy, downtime) are weighed.

For official VH54S.5PH6 components, trusted suppliers, and integration support, visit the certified distributor at https://ziskmagazine.com/

The VH54S.5PH6 isn’t just powerful — it’s certified for safety and regulatory compliance across multiple industries. It adheres to international standards such as:

- ISO 9001 / 13485 for quality assurance

- CE & RoHS for environmental and electrical safety

- ATEX/IECEx for explosion-proof applications in hazardous zones

- FDA and USP Class VI compatibility (for medical-grade applications)

These certifications prove that the component is not only high-performance but also legally and ethically ready for mission-critical deployment.

As industries adopt Industry 4.0 practices, the VH54S.5PH6 is designed to plug into:

- SCADA systems

- Edge computing platforms

- AI-driven quality monitoring

- Cloud-based analytics dashboards

It offers encrypted data transmission, real-time telemetry, and software-defined updates — making it future-ready in both hardware and software dimensions.

The VH54S.5PH6 supports custom firmware for tuning the component’s response profile. Engineers can:

- Adjust signal filtering for noise reduction

- Change latency behavior for faster or smoother feedback

- Enable built-in event logging and auto-calibration

This flexibility makes it not just a sensor or actuator, but an adaptive smart module customizable for each application.

From Germany to South Korea, VH54S.5PH6 has already made a difference:

- Automotive Plant in Munich: Reduced actuator failure rate by 78%

- Oil Rig in UAE Desert: Continued stable operation after 16 months without servicing

- Hospital in Tokyo: Helped surgical systems deliver 99.9% fluid control accuracy

These real-world success stories prove its performance isn’t just theoretical — it’s battle-tested.

VH54S.5PH6 comes in multiple variants depending on application:

| Variant Code | Description | Use Case |

|---|---|---|

| VH54S.5PH6-A | Analog-only, ultra-low latency | Robotics and motion control |

| VH54S.5PH6-D | Digital protocol with diagnostics | Industrial automation |

| VH54S.5PH6-MED | Medical-grade, sterile sealed build | Life sciences & hospitals |

| VH54S.5PH6-HT | High-temperature alloy and coatings | Aerospace and foundries |

Each configuration is designed to meet specific sector demands while retaining core reliability.

The VH54S.5PH6 is primed for next-generation manufacturing trends:

- IIoT Compatibility: Accurate real-time data feeds enable smarter analytics and optimized operations, unlocking predictive insights and automation.

- Demanding Automation: Keeps pace with faster, more precise robotics and collaborative machines, ensuring consistent production quality.

- Sustainability: Energy efficiency and durable construction align with green manufacturing goals and corporate responsibility.

- Supply Chain Resilience: High reliability mitigates urgent replacement needs, softening disruption risks caused by logistics delays.

This future-proof design ensures the VH54S.5PH6 will remain a vital asset as industries evolve.

The VH54S.5PH6 is more than a component — it’s a promise of operational excellence, engineered for the toughest conditions and highest stakes. It empowers industries from aerospace to medicine to mining, delivering peace of mind through superior reliability, pinpoint accuracy, and smart efficiency. For anyone serious about industrial performance, VH54S.5PH6 isn’t just a choice; it’s a competitive advantage. Investing in this model means investing in long-term success, minimal downtime, and peak productivity.

Q: What is VH54S.5PH6 exactly?

A: It’s a high-precision industrial component used for sensing, control, or actuation, designed specifically for demanding environments where accuracy and durability are paramount.

Q: How does it handle extreme conditions?

A: Built with advanced materials and sealing, it withstands temperature extremes, vibration, shocks, and corrosive agents, maintaining performance without compromise.

Q: Is installation complex?

A: No, it features standardized interfaces and clear documentation, simplifying setup and ongoing maintenance.

Q: Where to buy?

A: Contact the manufacturer or authorized distributors for official specifications, pricing, and support.

Q: Can VH54S.5PH6 be customized for specific applications?

A: Yes, modular design and flexible configuration options allow tailoring for unique industry needs.

For more visit at https://influencersgonewilds.site/